Dec / 05, 2025

Potential Application of Ecopower Crosile®-7270 in Photovoltaic Encapsulation: Reinforcing Interfaces for Long-Term Reliability

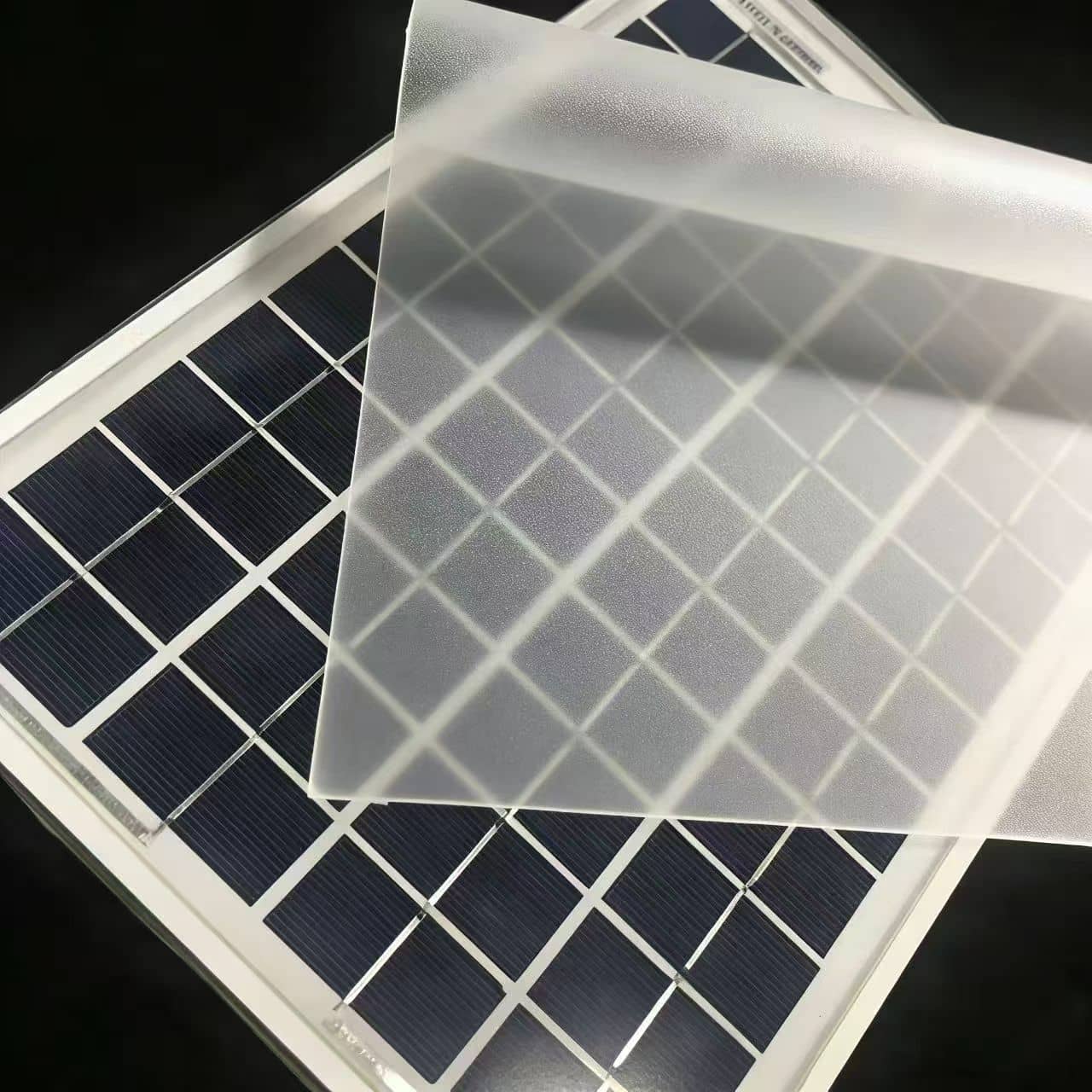

Introducing Functionalized Silane Polymer: A Path Toward Durable Interfaces As global PV installation continues to expand, the expected lifetime of modules has shifted from 10–15 years to 25–30 years of outdoor service. For encapsulation films such as EVA and POE, long-term reliability is no longer only defined by transparency or curing behavior. The durability of the interface with glass, backsheet materials, or inorganic fillers has become a core determinant of module stability. In practical field operation, encapsulation films often experience delamination, white spots, adhesive degradation, and component migration under high humidity, UV, and thermal cycling. These failures are not solely caused by insufficient crosslinking; in many cases, they originate from insufficient or unstable interfacial bonding. The use of silane additives in encapsulation formulations is not new. However, conventional monomeric silanes can present limitations such as high volatility, migration, and gradual loss of bonding strength over service life. In comparison, functionalized siloxane polymers offer a more stable interfacial design strategy. Crosile®-7270 is one such example: a methacryloxy-functionalized polymer siloxane that combines organic crosslinking capability with enhanced affinity toward inorganic surfaces. By interacting with both organic resin matrices and inorganic substrates, its structure is designed to create denser, more durable bonding at interfaces such as glass and filler-rich surfaces. Application Potential Based on Product’s Characteristics Crosile®-7270 exhibits a density of approximately 1.02 g/cm³, and a low viscosity of 1–2 mPa·s, enabling easy dispersion and low-treat-rate incorporation into EVA or POE compounds. With a SiO₂-related residue of around 34%, it offers a high density of potential bonding sites for glass, metallic surfaces, and inorganic fillers. Additionally, its higher boiling point and flash point help limit volatilization during vacuum lamination and thermal curing, reducing the risk of bubble formation or white spots often associated with volatile additives. These characteristics support its potential value in: interface durability, enabled by multifunctional bonding; reduced migration and volatilization, due to polymer structure; lamination process stability, linked to its high-boiling profile. Positioning in PV Encapsulation Film Development Based on these characteristics, Crosile®-7270 may serve as an interface-enhancing synergistic additive in EVA or POE formulations designed for high reliability. Its potential contributions include: Collaborative bonding within the crosslinking network of POE/EVA. Improved interfacial retention under damp-heat exposure or UV-thermal aging. Reduced white spots or bubble defects during lamination due to lower volatility. These possibilities depend on the formulation design and should be assessed through...

詳細をご覧ください

Whatsapp us

Whatsapp us